Rage Tube is on hold for now while I'm trying to finish up this other project done (almost done) and getting published if I can... (really should get one done and then start another one... sigh) So be back once I'm done~! (and that's why I've been MIA lately)

Oh, and no pics this time until I get response from the publisher...

Sunday, May 24, 2009

Thursday, May 14, 2009

Thursday, May 7, 2009

Random Update

Been playing around with mold making alot lately, trying to get the hanging of it before going back to sculpting. (and yes.... I spent around two weeks on it...)

Since there are some mold that I made previously and realized that I will not be using them ever again, I decided to recycle them and turn it in a new mold.

First, cut the old mold in to small cubes:

Then just mix it with some now silicon and pour it in:

Once it dries, is done. The cast turned out well, but I wouldn't recommend if you are planing to keep the mold in the long run. But very useful for making one time only type of mold.

So moving on, also tried to make a larger mold the other day, but it turned out to be a failure.

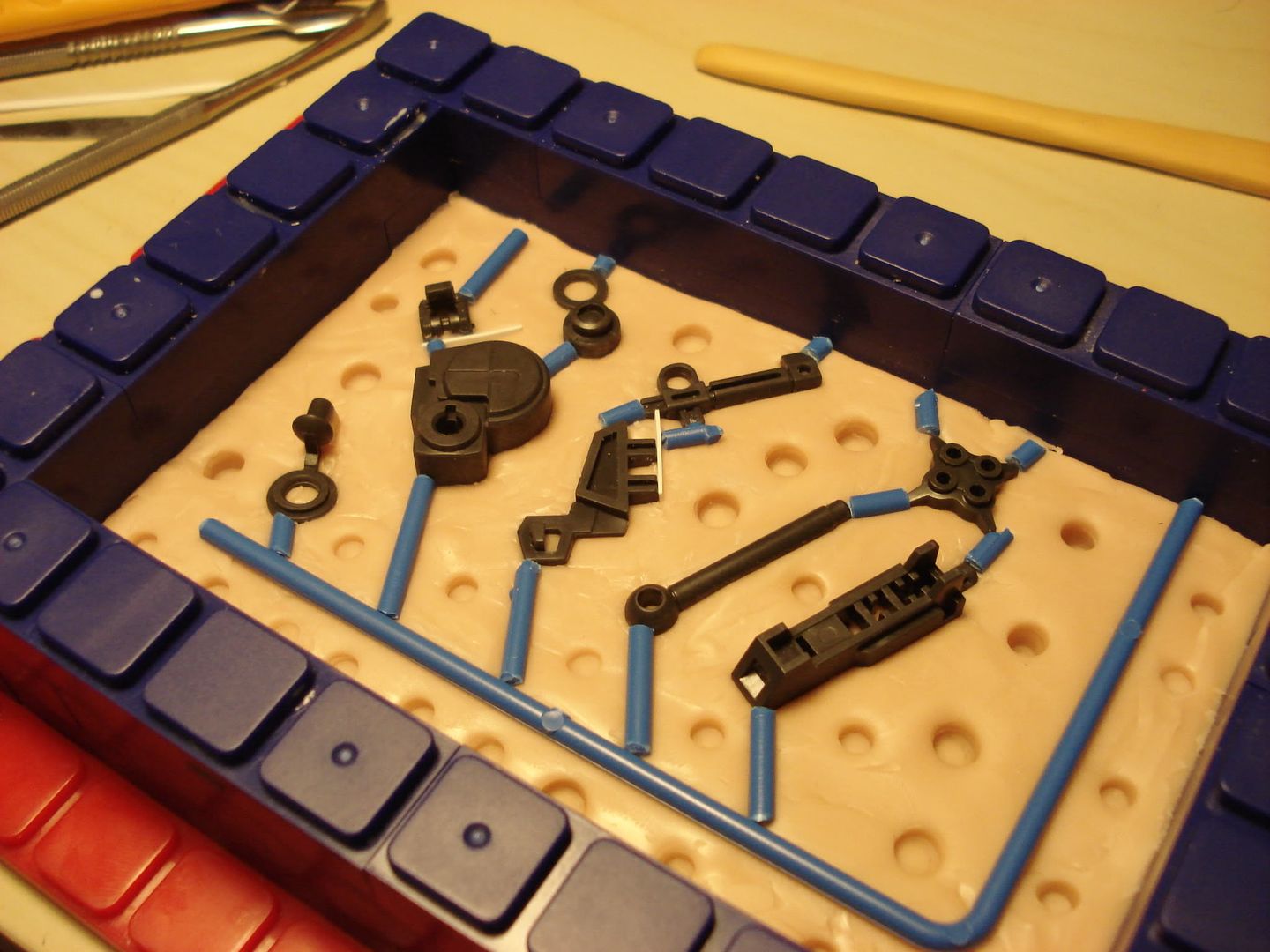

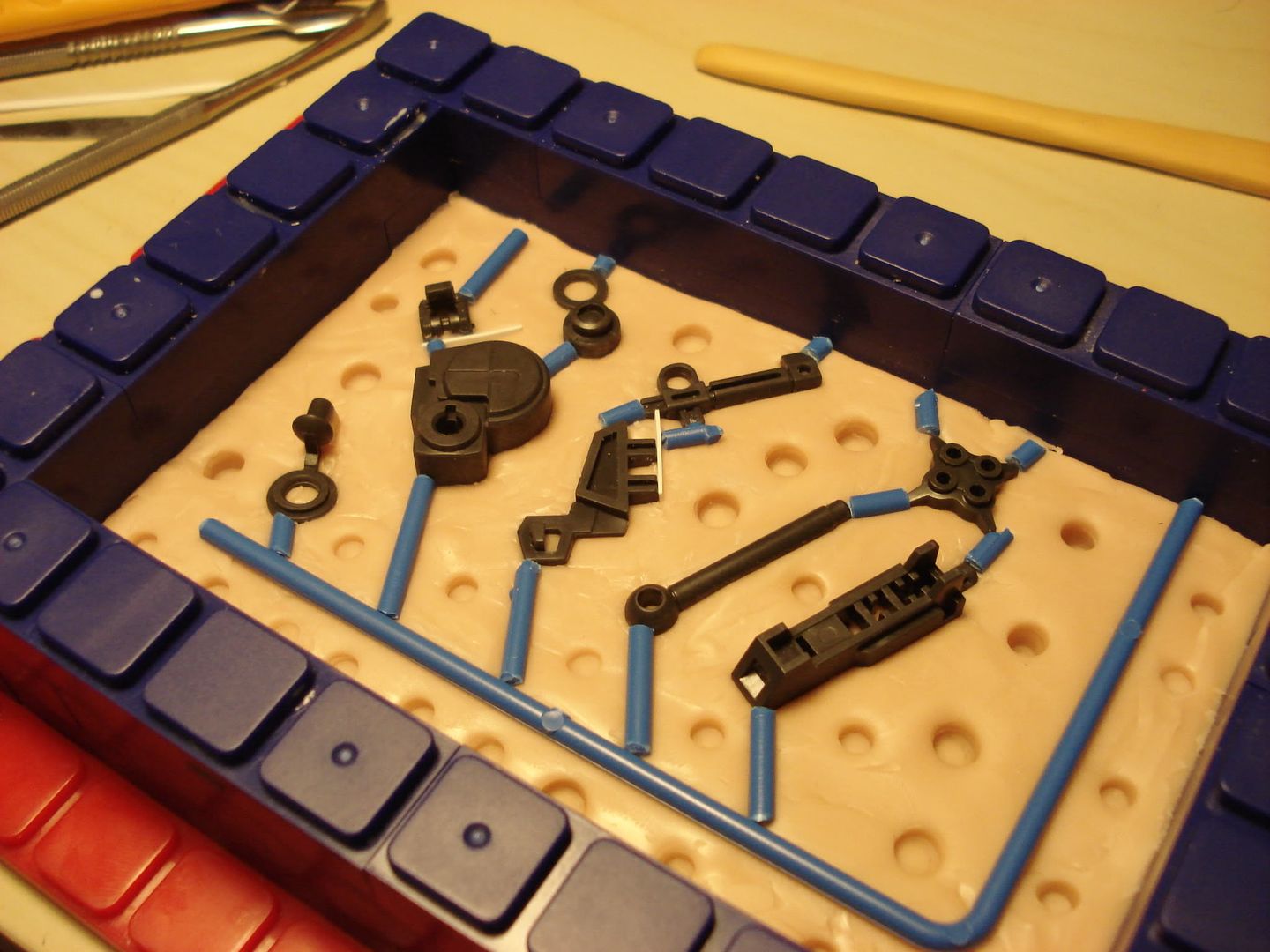

Here is the picture before the silicon been poured in:

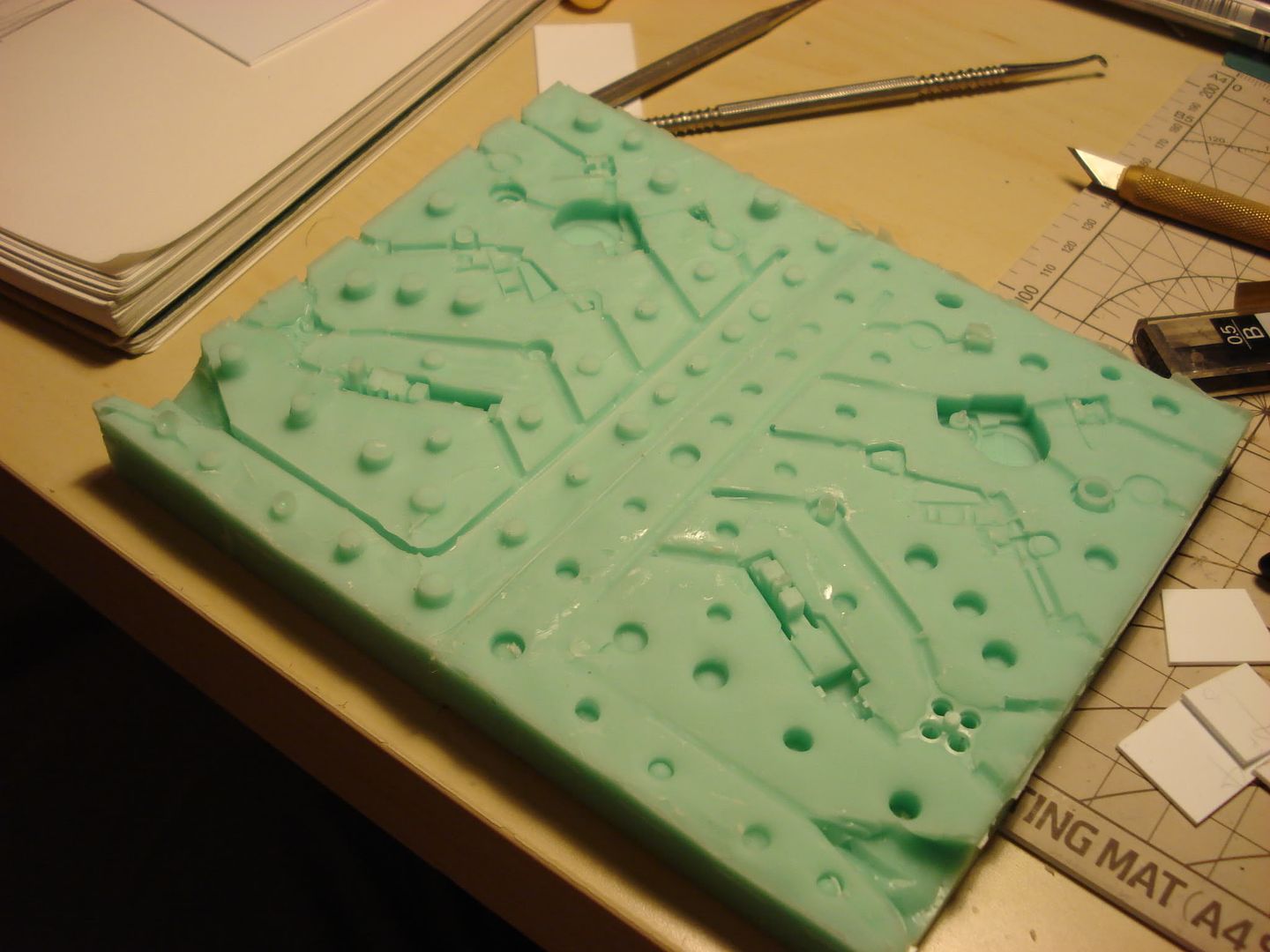

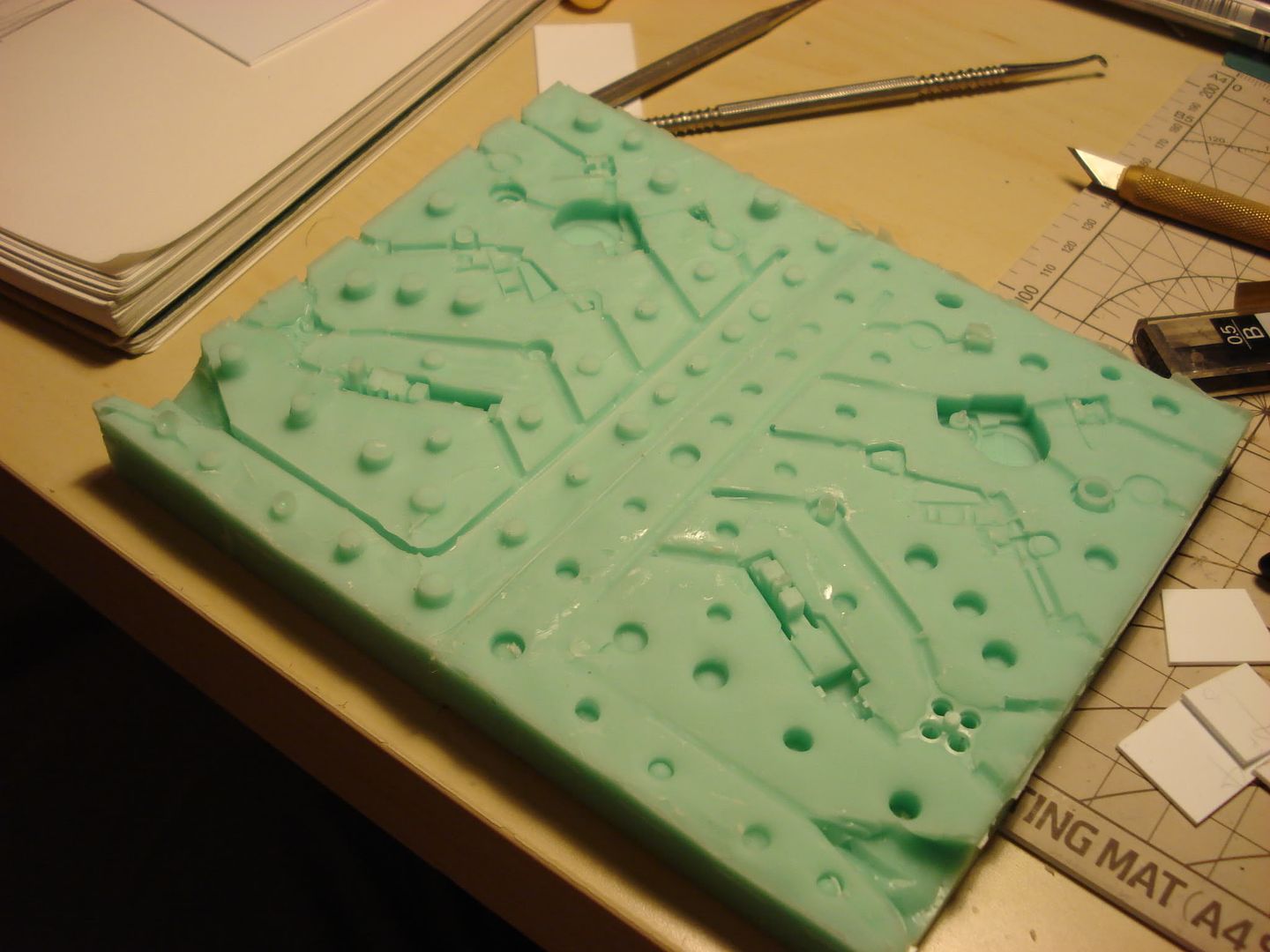

And here is the result of the mold:

The problem? Do to the fact that the pouring path is on the side,he resin can't travel fast enough to reach to the end of the mold. Also, the air is having a hard time to escape there are alot of details involved in each parts. The correct way should be playing the pouring path in the middle of the mold, and keep the mold simple, which will result in better casting quality.

Will be going back and remake the mold soon.

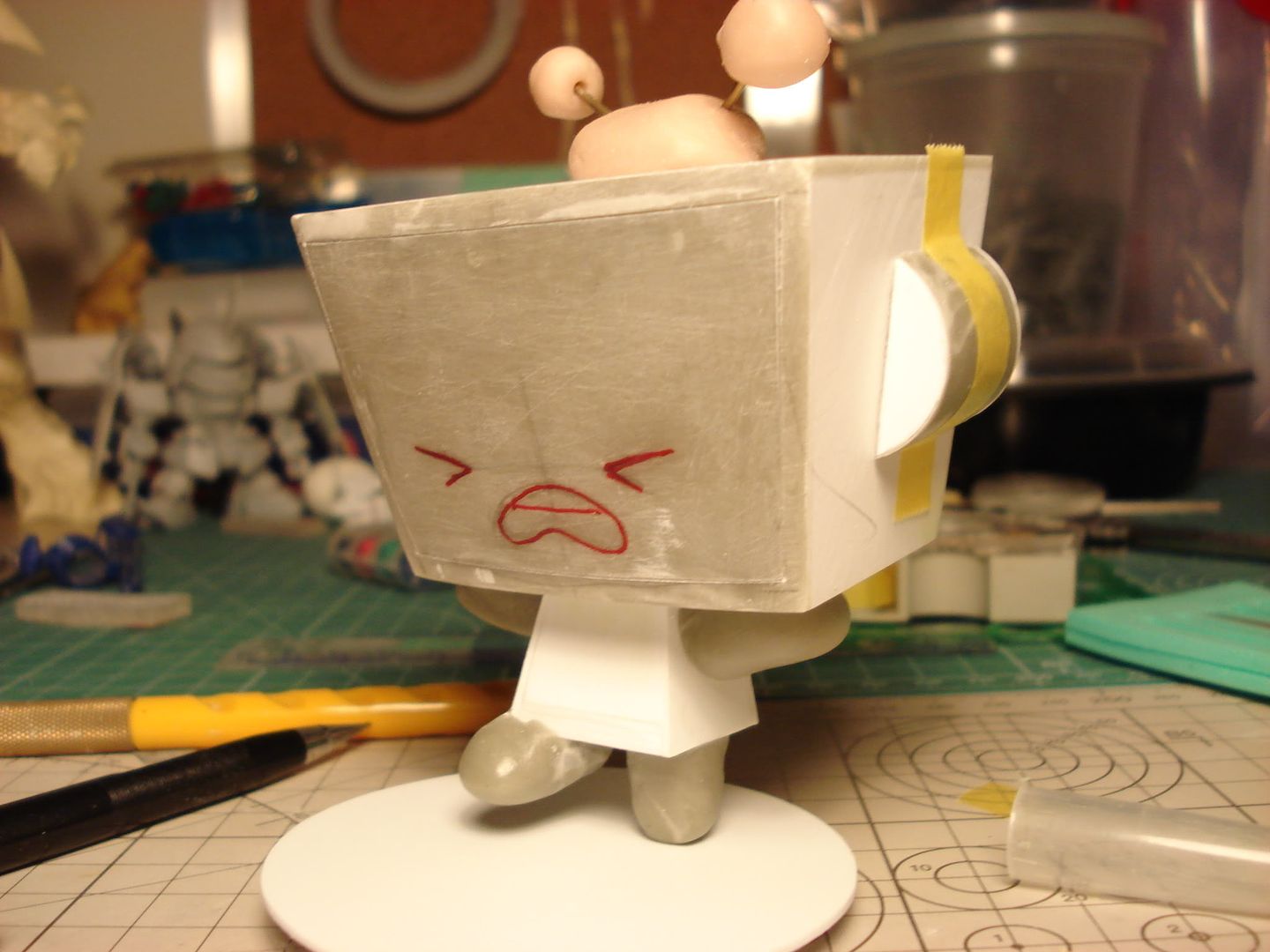

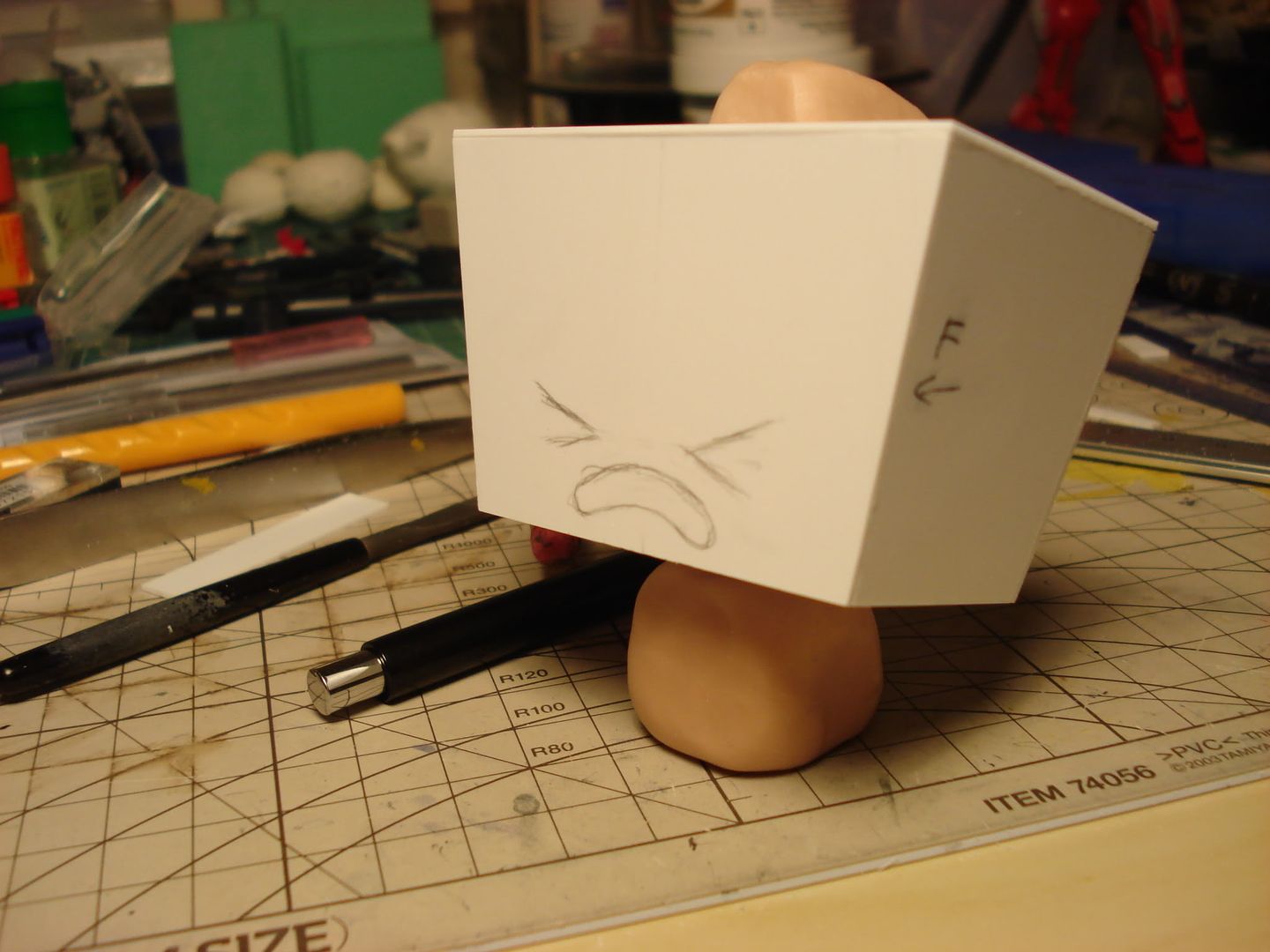

And... is time for some sculpting work...!

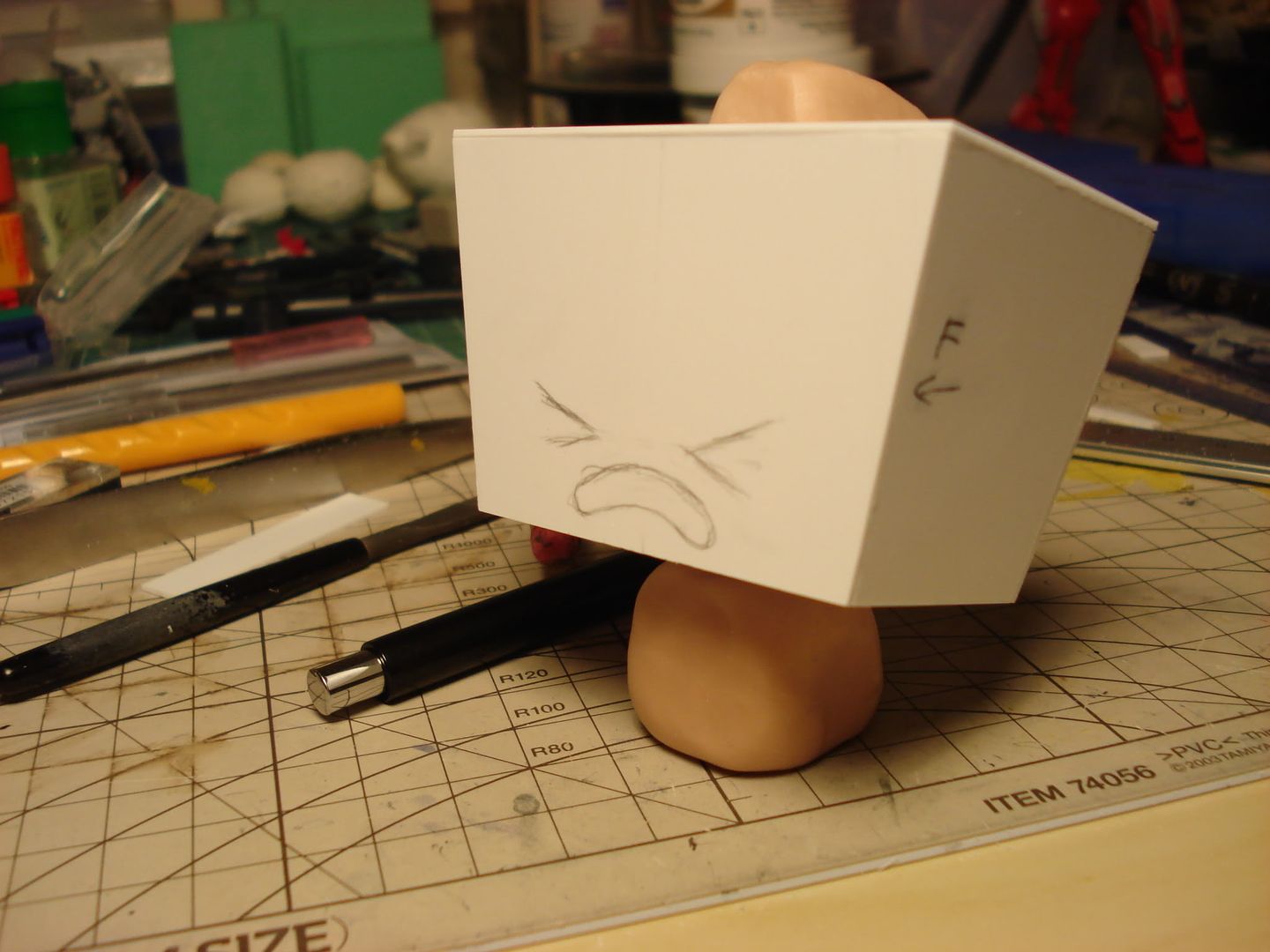

So here is a few hour work-out for today:

Since there are some mold that I made previously and realized that I will not be using them ever again, I decided to recycle them and turn it in a new mold.

First, cut the old mold in to small cubes:

Then just mix it with some now silicon and pour it in:

Once it dries, is done. The cast turned out well, but I wouldn't recommend if you are planing to keep the mold in the long run. But very useful for making one time only type of mold.

So moving on, also tried to make a larger mold the other day, but it turned out to be a failure.

Here is the picture before the silicon been poured in:

And here is the result of the mold:

The problem? Do to the fact that the pouring path is on the side,he resin can't travel fast enough to reach to the end of the mold. Also, the air is having a hard time to escape there are alot of details involved in each parts. The correct way should be playing the pouring path in the middle of the mold, and keep the mold simple, which will result in better casting quality.

Will be going back and remake the mold soon.

And... is time for some sculpting work...!

So here is a few hour work-out for today:

Subscribe to:

Comments (Atom)